Steeltec offers a solution for all your requirements regarding the manufacture and welding of different types of steel structures and components in one place. With a production capacity of over 5,000 tons of steel structures per year, Steeltec is very suitable for projects of all sizes and requirements such as: industrial facilities, heat exchangers. bridge cranes public facilities, special constructions (tanks, silos, tanks).

STEEL PRODUCTION

Production of steel structures of industrial facilities

For many years on the market we offer the production of steel structures for various purposes for the needs of investors:

- Metal halls

- Prefabricated halls

- Warehouses

- Production facilities

- Roof racks

- Construction for sports halls

- Shopping malls

- Various industrial and storage facilities

Within our company we have a team that performs:

- Roof covering: “stacked system” of covering as well as covering with roof panels

- Facade cladding

Production of heat exchangers

Our company has experience in making heat exchangers. So far, we have produced over 65t of black and stainless steel heat exchangers. We make products for both domestic and foreign markets.

Construction of bridge cranes

Bridge cranes are used for cargo handling in production halls, workshops, storage space, etc.

Depending on the required load capacity, installation possibilities and range, we offer the production of:

- Bridge cranes (single-row and double-row)

- Crane tracks

- Portal cranes

Construction of public facilities

Steeltec offers the design and manufacture of all types of steel structures for public facilities, such as hospitals, open and closed sports facilities, traffic light portals, level pedestrian crossings, markets and the like.

Special constructions (silos, tanks and cisterns)

Silos, tanks and cisterns are made in various sizes and shapes according to the needs of the Investor. They can be made of different materials such as stainless steel (aluminum), aluminum, black steel (.

Most of these assemblies are made as pressure vessels, for which our company has experience in production.

OUR MACHINES

SHOT BLASTING

Vertical flow towel rack – shotgun, dimensions 1000x2000mm

H BEAM STRENGTHENING

Longitudinal welding line using EPP technology

HZJ 1020/1025

Assembly machine for H beam 1000x2500mm

HGP 1018 – 8

Shoot – blasting and cleaning machine 1000x1800mm

G25HPE FICEP – GEMINI

Gantry automatic CNC drilling, milling & thermal cutting system for large plates 2500x12000mm

FRONIUS 400A t

Devices for welding MIG – MAG

Euroslitter

Cutting services aluminum, galvanized, stainless steel coils thickness 0.2 – 2mm

DOUBLE COLUMN WELDING

Machine for assembling H beams up to 2000mm

SXBH 20

Double’s column welding machine 800x2000mm

Müler opladen GMBH

Tubes cutting and marking machine φ30 – 914mm x 60mm

RB2506 – 6/11 Ficep wheelabrator

Roller conveyor shot blast machine type roto yet 2500x500mm

Sector for mechanical engineering processing

Promotec hyperterm hpr 130

Plasma and gass cutting

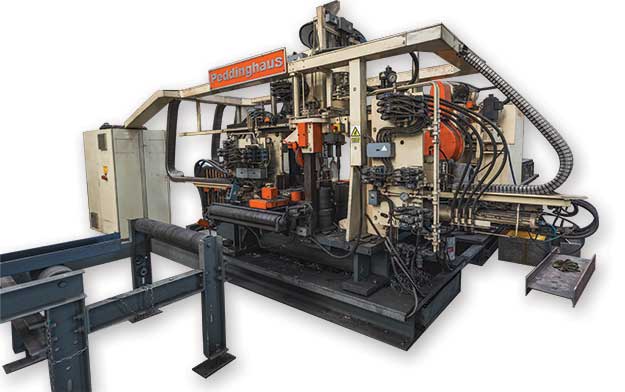

Pedding house

Cutting & drilling 300x1000mm

ASSEMBLY FOR H BEAM

Line for cold ironing of H beams after welding

YJZ – 60c

H – beam hydraulic straightening machine 800x>350mm

1203 VLB FICEP – VALIANT

Automatic CNC drilling & sawting line 610x1220mm

COSTA GRINDING MACHINE

Flow line for grinding, cleaning and deburring the edges of flat materials

Shootblasting machine

Metal sheet bending machine 30mm thickness

Metal sheet bending machine of 10 – 120mm x 3000mm thickness

MACHINING, CUTTING AND DRILLING

Steeltec has the ability to process high quality components of various sizes, materials and specifications. Cutting, mowing and drilling can also be automated with superior precision. Using state-of-the-art CNC machines and qualified operators, Steeltec offers:

- High-precision CNC lathes for turning pieces up to 2.5 m long

- Gas and plasma cutting plates up to 200 mm thick

- Precision drilling, grinding and milling

- Slab contraction joints (width up to 3 m and thickness 10 mm)

- Manual cutting of edges for preparation of welds

WELDING

Welds are one of the most important characteristics of steel construction and expertise, knowledge and experience greatly contribute to the assurance of the structure:

- Welding of different materials and special types of steel

- IWE / EWE qualified welding engineers

- International standards and welding codes: AWS, ASME, API, BS, ISO, CEN

- Manual, semi-manual and automatic welding

- Welding technologies: MIG / MAG, TIG

- Non-damaging test (NDT)

BLASTING AND COATING

A quality coating system, whether with protective paint or galvanizing, is important for the aesthetics and durability of the steel structure. Steeltec offers a wide range of available coating system options to suit many projects. Another aspect that is often overlooked is the packaging system that Steeltec offers to ensure that your product arrives at your location with minimal or no damage to the coating.

- Combination of manual and semi-automatic application methods for consistent thickness and ability to apply in hard to reach places

- Sandblasting according to different standards

- Various coating options – colors, types

- Careful control of humidity and temperature

TESTING (MATERIAL, WELDING, COATING, DIMENSIONS)

Testing at all stages of development is crucial in the quality assurance process. All products manufactured by Steeltec follow a strict inspection and test plan with different retention points to check the components for strength and defects. Steeltec offers a complete package and expertise in testing steel structures:

- Highly accurate, routinely calibrated and certified dimensional measurement equipment

- ISO, EN 1090, ISO 3834 and other certificates

- Close relations with reputable independent engineers for testing of welded joints MT, RT, PT, VT

- Coating overview – thickness, imperfections, adhesion

ENGINEERING

Steeltec offers clients a dedicated project engineer for every order, communication and technical inquiries. This makes project management easier for both the company and the clients. We understand the need for close interaction with contractors, design consultants, owners and other stakeholders in the project.

– Engineering calculations in accordance with standards

– 2D and 3D CAD drawings of details, welding and more

– Finite element analysis

– 3D visualization and animation services

INSTALLATION OF STEEL STRUCTURES

With a production capacity of over 5,000 tons of steel structures per year, the Steeltec company is very suitable for projects of all sizes and requirements.

The assembly of our steel structures is completed economically and on time. Our operational team helps to ensure a smooth assembly process, ensuring proper transport of materials, unloading and storage, as well as adequately prepared spaces for lifting and installation.

In order to ensure smooth operation and quality installation, every aspect of our work is constantly checked. Steeltec obtains documentation of the assembly plan, preparation of the assembly according to the drawings, provides a location plan with detailed information on the location and coverage of cranes, workers, unloading and storage areas, access to workplaces and safety criteria.

Steel assembly involves the assembly of metal structures by joining steel beams, columns and slabs.

MECHANISM FOR ASSEMBLY IN THE FIELD

MAN TGX trucks

MAN TGX trucks

Type: 18.400 and 18.440

Liebherr LTM 1025 - 25t mobile crane

Type: Telescopic car crane

Max. load: 25 t per 2.5 m

Axles: 2

Total weight: 24t

Telescopic characteristics

Telescopic arm: 8.4-26m

Number of arm segments: 4

Dimensions

Length: 9660 mm

Weight distance: 2800mm

Platform length: 8155 mm

Width: 2500mm

Engine: LH D 916TI

Power: 180 kW / 245PS

Max. torque: 1020 Nm1300rpm

Transmission

Lastschalt-Wendegetriebe axles: 6 + 2 (forward + reverse)

Max. speed: 75km / h

Control (standard): 4x4x4

Terex Boom

Type: TB 85

Working height: 27.50 m

Terex Demag AC 50t mobile crane

Type: Telescopic service crane

Max. load capacity: 50 t per 2.5 m

Axles: 3

Total weight: 40 t

Telescopic characteristics

Telescopic arm: 40 m

Dimensions

Length: 11,200 mm

Haulotte HA16PX Boom Lift - 2 pieces

Engine

Manufacturer: Deutz

Total power: 31kw

Fuel type: euro diesel

Weight: 7.000kg

Tank capacity: 72L

Hydraulic system capacity: 100L

Top speed: 5.5 km / h

Tire size: 385 / 65-22.5

Tire filling: foam

Platform

Maximum working height: 16,000mm

Maximum platform height: 14,000mm

Maximum horizontal extension: 9,100mm

Maximum load in the basket: 230kg

Platform length: 1.800mm

Platform width: 800mm

Genie Boom

Type: S 85

Working height: 34 m

MinoEge 40 RTS

Dimensions

Overall length: 3,780 mm

Overall width: 2,290 mm

Wheelbase: 2,490 mm

Ground clearance: 304.8 mm

Basket

Max. platform height: 12,040 mm

Basket width: 1,800 mm

Basket length: 3,200 mm

Basket extension: 1,220 mm

Fence height: 1,100 mm

Engine

Manufacturer: Ford

Model: VSG-413

Engine power: 26.1 kw

Fuel type: Diesel

Characteristics

Weight: 4717.4 kg

Tank capacity: 56.8 L

Hydraulic system capacity: 75.7 L

Top speed: 5.6 km / h

Tire size: 12 x 16.5

Platform

Max. platform load: 453.6 kg

Descent time: 35 sec